KHS CoolFlow Chiller

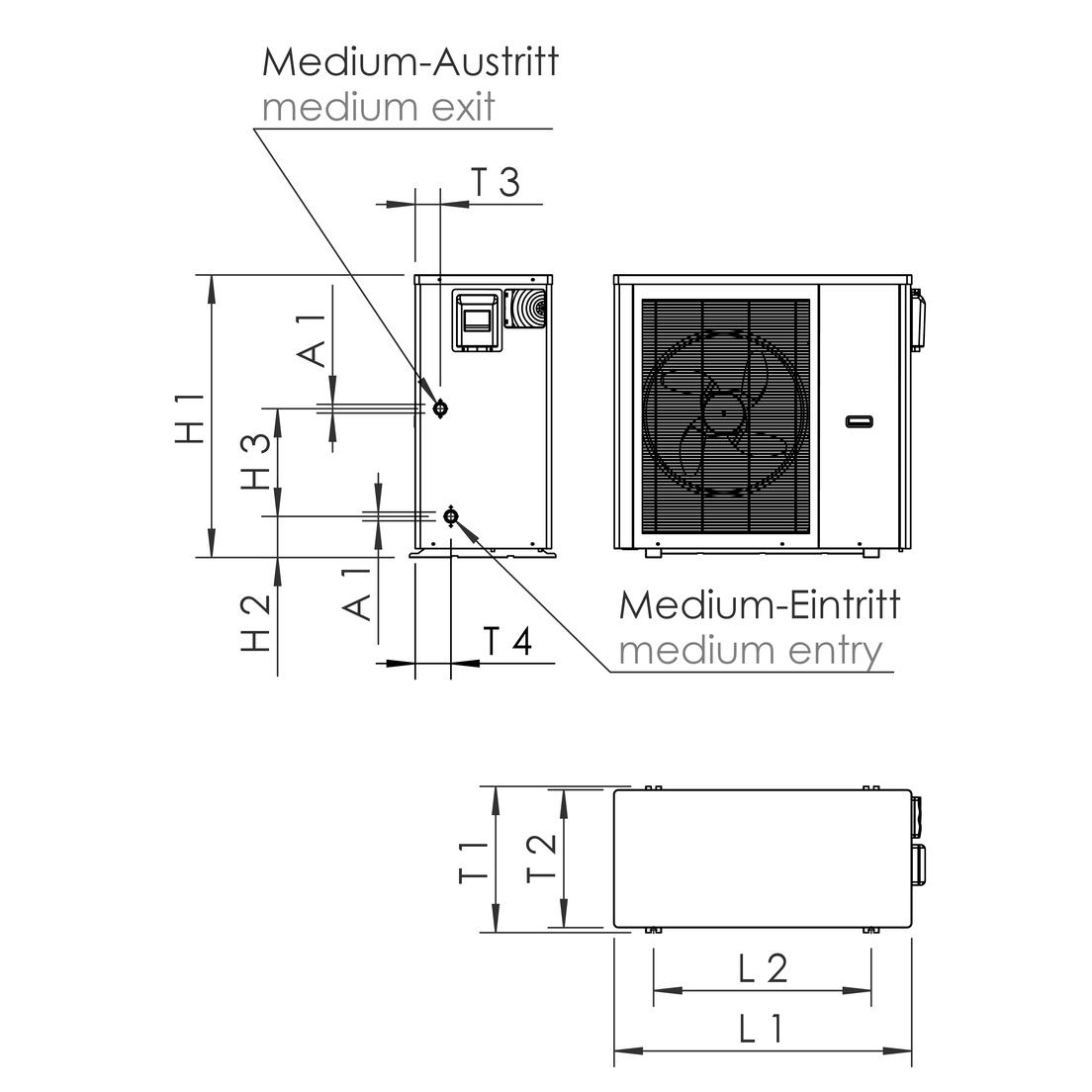

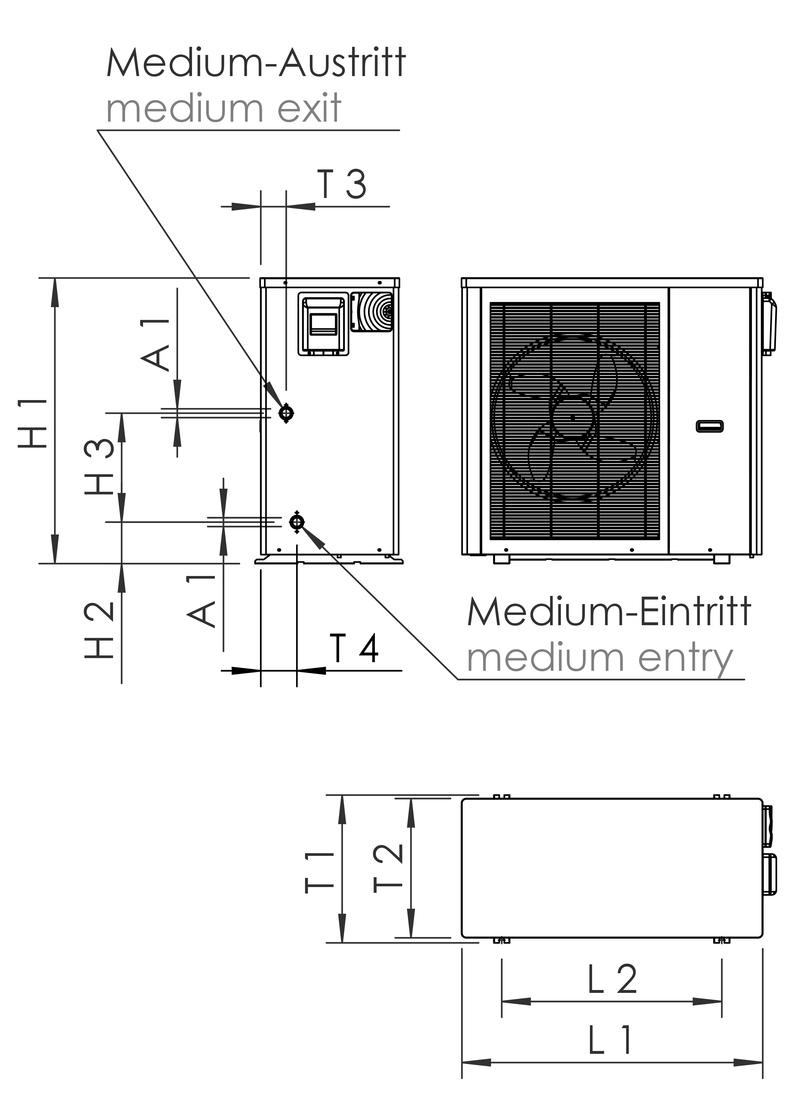

figure 618 01

1. for cooling the KHS CoolFlow cold water cooler

2. air-cooled chiller in compact design for outdoor installation for energy-efficient operation of the KHS CoolFlow cold water circulation

3. weatherproof base frame with removable cladding panels made of powder-coated steel, colour similar to RAL 9010

1. for cooling the KHS CoolFlow cold water cooler

2. air-cooled chiller in compact design for outdoor installation for energy-efficient operation of the KHS CoolFlow cold water circulation

3. weatherproof base frame with removable cladding panels made of powder-coated steel, colour similar to RAL 9010

Product Features

- for cooling the KHS CoolFlow cold water cooler

- air-cooled chiller in compact design for outdoor installation for energy-efficient operation of the KHS CoolFlow cold water circulation

- weatherproof base frame with removable cladding panels made of powder-coated steel, colour similar to RAL 9010

- with infinitely variable cooling control

- modern EC fans and integrated fan control to reduce operating costs and optimally adjust the fan speed to the actual ambient conditions

- infinitely variable speed regulation through thermal low-noise fan control for particularly low noise emissions

- standard operating limits from -15°C to +45°C

- fully hermetic, vibration-damped rotating-piston inverter compressor for infinitely variable adjustment of the compressor frequency, with refrigerator oil filling

- refrigerant circuit made of refrigerant copper pipe, hermetically sealed and pressure tested at the factory, dried and filled with R410A safety refrigerant

- controllable via Schrader valve

- High- and low-pressure control device, filter dryer and electronic expansion valve to increase energy efficiency and improve control quality

- evaporator as refrigerant-water heat exchanger as tube bundle heat exchanger, vapour-diffusion-tight insulation, return temperature range from +10°C to +20°C

- insulated medium circuit with manual bleeder valve, differential pressure monitor for monitoring the volume flow, and speed-controlled circulation pump according to the specifications of the Ecodesign Directive

- medium connections in solid design with one-inch female pipe thread

- internal control box with terminal strip for mains power supply, contact for external release and potential-free contact for collective fault signal

- completely wired and tested main and control circuit with transformer, control fuses to protect the device's PCB

- automatic restart after power failure

- modern touch controller in IP54 splash-proof body for operating the device and setting further operating parameters

- RS485 Modbus interface as standard

- clear display of medium inlet and outlet temperature as well as function display of fan, compressor, required maintenance interval and elementary faults, such as high/low and differential pressure

- coded fault messages and display of all operation-relevant control parameters with password-protected access

- compliance with all requirements of the Ecodesign Directive (EU) 2016/2281 (LOT 21) through optimized heat exchanger surfaces, use of high-efficiency components and optimisation of operationally relevant system parameters

- *air inlet temperature 35°C dry bulb, medium temperatures 7/12 °C, 0% glycol concentration

Technical data

- protection class IPX4

- power supply 230V AC

- Sound pressure level (distance 10 m free field) 37.3 dB(A)

- sound power level 68.5 dB(A)

- adjustment range, return temperature +10 to +20°C

- operating range -15 to +45°C

- max. air volume flow 3900 m³/h

| Part no. | Cooling capacity (kW) |

SEER | A1 | H1 (mm) |

H2 (mm) |

H3 (mm) |

L1 (mm) |

L2 (mm) |

T1 (mm) |

T2 (mm) |

T3 (mm) |

T4 (mm) |

Room cooling annual utilisation factor (%) |

max. electrical power consumption (A) |

adjustment range return temperature [°C] |

refrig- erant |

Refrigerant basic quantity (kg) |

sound pressure level (distance 10m free field) |

CO2 equivalent (t) |

sound power level |

Nominal power consumption (kW) |

Nominal current consumption (A) |

Nominal flow rate, medium (m³/h) |

kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6180100100 | 4.7 * (1.6-5.6) | 4.57 | G 1 | 790 | 98 | 312 | 1008 | 750 | 490 | 463 | 102 | 102 | 152 | 9.2 | 10 to 20 | R410A | 2.5 | 37.3 | 5.22 | 68.5 | 1.3 | 5.6 | 1.0 | 95 |

| 6180100200 | 7.6 * (2.0-10.0) | 5.51 | G 1 | 910 | 98 | 380 | 953 | 700 | 470 | 445 | 80 | 114 | 170 | 18.0 | 10 to 20 | R410A | 2.4 | 37.3 | 5.01 | 68.5 | 2.3 | 10.4 | 1.6 | 120 |